Chipquik Solder Paste in Jar 50g (T3) Sn63/pb37 Review

T4 new industry standard

Contains Silvery

2 dispensing tips

Pneumatic Dispenser

No Clean Flux

Excellent Wettability

T4 new industry standard

183C 361F Melting Point

2 dispensing tips

Leaded

No Make clean

Jar

Alloy: Sn63/Pb37

Synthetic No-Clean

Flux Nomenclature: REL0

Clean

Prevents metal oxidation

Acts as a wetting agent

Contains a No Clean Flux

96.5 / 3.5 Tin/Argent

Comes with Plunger and Tip

Lead Free

Cadmium Gratis

Has a stiff flux

35 grams of solder paste

v 19-gauge dispensing tips

63/37 Tin/Lead

No make clean

T5

15g

Choose the All-time Solder Paste

Customer'due south Choice: the All-time Rated Solder Pastes

828 users answered this survey. Please help usa better this review!

76.45% of users selected Temperature Solder Paste, 7.73% selected MG Chemicals, 4.71% selected 247 Solder, 7.49% selected Flake Quik Electronic and 3.62% selected Bit QUIK SMD291AX. Every month we analyze your answers and change our rating.

What is Solder Paste

Solder pastes are a blazon of aqueous or solvent-based chemical material, fabricated upwardly of tiny solder assurance that, when combined with flux and other chemical products, brand what is called solder paste.

Solder paste usually requires cold storage and brought to room temperature when ready to be used.

Solder paste is widely used in SMD component electronics, SMD only means Surface Mounted parts, but also in traditional electronic component soldering, and is mostly used to improve solder quality.

The solder paste is usually applied using a stencil or direct to the areas to be soldered, and allows, among other things, to eliminate the possible rust existing in the metallic components improving the quality of welding, only information technology too acts as a heat concentrator and this allows its distribution to exist much more homogeneous.

The tiny solder balls mentioned earlier, come in different sizes, T3, T4, T5, etc. the higher the value, the smaller the solder assurance.

As on the market, you can find a great multifariousness of pastes. Therefore, here you volition discover reviews of wonderful options and the buyer'southward guide to larn more than most them.

Chip Quik SMDLTLFP Solder Paste Sn42/Bi57.6/Ag0.4 No-Clean Atomic number 82 Free

If you are looking for a low-temperature, No LEAD, No-Clean solder paste, this Chip Quik paste is excellent. This solder paste for electronics tin be used for prodotypes or production where the use of soldering pastes based on SAC alloys is not possible due to temperature-sensitive components or circuit boards.

If you are looking for a low-temperature, No LEAD, No-Clean solder paste, this Chip Quik paste is excellent. This solder paste for electronics tin be used for prodotypes or production where the use of soldering pastes based on SAC alloys is not possible due to temperature-sensitive components or circuit boards.

If you need RoHS compliance apply this paste, otherwise use the Leaded version every bit it is easier to work with and has a lower melting betoken.

It comes in a syringe with two dispensing tips. Information technology allows you to control the amount of paste yous demand. Moreover, they help to accurately apply soldering paste simply to the needed places. As it contains silver, it has less brittle join and you do not need high temperatures to melt it. It melts at around 281 Fahrenheit/138 C.

- This flux soldering paste has the lowest soldering temperature being No Lead;

- No demand to clean the paste later on soldering;

- With this paste your welds look shiny.

- Information technology is not uniform with an automated air-paste dispenser.

MG Chemicals – 4860P-35G

While dealing with electronics, it is very important to utilise a small amount of flux to the needed areas. Craftsmen often utilize pneumatic dispensers with precise control. MG Chemicals offers you 4860P-35G flux paste in a syringe that is compatible with such devices. If you prefer to get more than flux per buy, this make has larger jars.

While dealing with electronics, it is very important to utilise a small amount of flux to the needed areas. Craftsmen often utilize pneumatic dispensers with precise control. MG Chemicals offers you 4860P-35G flux paste in a syringe that is compatible with such devices. If you prefer to get more than flux per buy, this make has larger jars.

This solder paste contains atomic number 82. It saves the amount of time you need to wait before starting the soldering process. Moreover, the melting temperature is also lower. It is safer to work on vulnerable pieces. With MG Chemicals 4860P-35 Thousand paste, you oestrus your tip to 360 Fahrenheit.

- You do not need to apply much forcefulness to use get the past exterior of the syringe;

- It can exist used non just for soldering but also for surface mount, rework, component bonding, etc.;

- This flux does non cause corrosion to metal details.

- It has a stiff chemic smell and it is not very good for sensitive noses.

247 Solder SnPb Leaded Solder Paste

In case you exercise not desire to spend too much money on a nice soldering paste, in that location are e'er more affordable options. On the market, you can find 247 Solder SnPb paste of a off-white price and quality. It arrives in a syringe with 2 dispensers. To melt it you simply need a temperature of 361 Fahrenheit.

In case you exercise not desire to spend too much money on a nice soldering paste, in that location are e'er more affordable options. On the market, you can find 247 Solder SnPb paste of a off-white price and quality. It arrives in a syringe with 2 dispensers. To melt it you simply need a temperature of 361 Fahrenheit.

SnPb ways that flux contains tin and lead. This type of flux is not that pop merely information technology tin can impress users with proper corrosion resistance. Moreover, information technology is suitable for dealing with electronics. SnPb has squeamish electrical properties that allow making solder joints that will suffer mechanical strength.

- Information technology does non crave cleaning after soldering;

- Flux is compatible with hot air guns and flame torches;

- The solder paste wets in a curt time.

- This flux cannot be stored for many years.

ChipQuik Leaded Solder Paste for Electronics – Professional Grade

Solder paste for soldering is ofttimes sold in syringes. Nonetheless, when yous need more than amounts of its jars is amend. ChipQuick offers a squeamish solder paste that you tin go far a jar of 8.8oz. This brand exists for many years on the market and it delivers various soldering equipment.

Solder paste for soldering is ofttimes sold in syringes. Nonetheless, when yous need more than amounts of its jars is amend. ChipQuick offers a squeamish solder paste that you tin go far a jar of 8.8oz. This brand exists for many years on the market and it delivers various soldering equipment.

This is a Leaded paste focused primarily on electronics. As it belongs to a no-clean category, you may not worry well-nigh corrosion. In that location can be small residues, which practise not require cleaning after soldering.

- The jar has plenty of flux paste for a multitude of soldering tasks;

- Yous can shop it in a fridge or freezer to prolong its shelf-life; (they have a TS version, thermally stable, does non need refrigeration)

- It does non crave high temperatures to cook.

- To employ flux paste you demand to employ a modest tool, which is not included in the purchase.

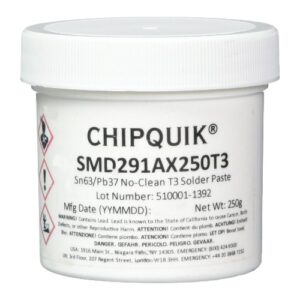

ChipQuik SMD291AX

Another nice product from ChipQuik for soldering is SMD291AX soldering paste. It arrives to customers in a syringe.

Another nice product from ChipQuik for soldering is SMD291AX soldering paste. It arrives to customers in a syringe.

Information technology is primary awarding is reworking. With a modest nozzle, y'all tin can hands utilize enough corporeality of paste to the identify and so begin soldering. It is suitable for electronics every bit flux paste does non cause corrosion and you practice non clean it.

- It is suitable for repairing electronics;

- Flux easily melts fifty-fifty using correct subsequently fridge;

- Y'all tin can apply the syringe without a nozzle to apply more flux at a time.

- The paste needs more force to push it out.

Best Solder Paste for Stencil and SMD

If you desire a solder paste that can work well with your stencil, I can strongly recommend:

1. ChipQuik TS991AX500T4 – This is a thermally stable (no refrigeration needed). It comes in a jar, which is best because, before each use, you need to stir it well. To practice this, I utilise a flat head screw bit tip and my cordless drill. Makes for a perfect stir stick and easy clean up.

I like the T4 size because it works well for my 0402, WFBGA, and small pitched parts.

Besides, yous may demand to as a bit of flux to re-hydrate the paste after a long fourth dimension of no use, then, I utilize the ChipQuik SMD291 no-clean flux for this. Just squeeze a small amount into the jar and stir.

Brand certain you lot don't add too much. Likewise liquid/runny and you lot will get poor solder flow when information technology comes out of the reflow oven. If the paste is too dry out, y'all will go clumps and your parts may not stick to the board from the pick-n-place.

How to Use Solder Paste

Solder paste is usually applied using a stencil. The stencil is a piece of thin metal with cut outs in in that lets the paste through to sit down exactly on the solder pads of your PCB.

And so a pick-north-place motorcar places your parts on the area where the paste is.

You would put a small amount of solder paste on your stencil, so, putting slight downwards pressure, employ a scraper to slowly pull the paste along the length of your PCB panel. Then gently elevator up the stencil and you are washed.

The Heir-apparent'due south Guide

Solder pastes are specific substances with a paste-similar consistency that are used to prepare parts. They accept sure advantages and disadvantages, likewise as application features. The principal field of application of flux paste for soldering electronics. It can be used for:

- Micro soldering, with or without lead;

- Integrated circuits;

- Soldering of diverse components, SMD or circuits;

- Cleaning debris and residues.

Types of Flux on the Marketplace

Solder pastes are distinguished mainly by 3 characteristics, the blazon of flux, its packaging, and its shape.

Flux Types

- Rosin Flux. It incorporates acid components derived from coniferous rosin, mixed with solvents. Rosin fluxes are used with a tin-lead alloy to solder electronic parts considering they do non leave a corrosive balance. Still, you should keep in mind that they exercise leave a sticky residual that attracts wet and clay and that you should clean with liquids such as trichloroethane.

- Organic Acid Flux. This is a mixture of acids mixed in booze or h2o without rosin, inorganic components, or solvents. Normally, they have a maximum of one-third of the traditional flux. Its apply is limited to cases where the rosin flux is non agile enough. I of their advantages is that they do not usually leave residues and tin exist cleaned with water. The truth is that most fluxes used in electronic devices are of this type.

- Inorganic Acid Flux. This blazon is too a mixture of hydrochloric acid, zinc chloride, and ammonium chloride. It is an active type of flux and is often used to weld metals such as bronze, copper, or even stainless steel with tin can and lead alloys, in domestic plumbing piece of work, or likewise in industrial environments.

- Brazing flux. It is completely different from the previously mentioned ones, and its composition of chemic elements is much more complex. However, its apply is like. You lot mainly use it to remove rust from the parts to be welded.

Varieties of Shapes

Although the most mutual form in which you volition find solder paste is liquid, y'all should know that at that place are up to four dissimilar ways to find this product on the market:

- Aerosol;

- Paste;

- Liquid;

- Dust.

Packaging Type

Perhaps i of the lesser-known aspects is the packaging of solder pastes. Information technology is important to consider information technology and then that its application is as comfy as possible. In the market, yous volition find three types of packaging:

- Syringe;

- Jar, tin, or bottle;

- Marker pen.

Use tips

- Security. Always apply rubber tools when you lot are going to use solder pastes. Remember that it is a element that can harm you lot and therefore you lot must do farthermost precautions during its use in all senses.

- Storage. Each manufacturer has its storage requirements, only remember that these types of products should be stored in places at absurd, but non extreme, temperatures. Make sure to avoid straight sunlight or in areas with high temperatures.

- Earlier using it, you lot must make sure that 24 hours earlier the solder paste must have been at room temperature, otherwise, you will not be able to use it correctly and you will lose all the properties of the solder with a flux that the product gives you.

Whatever welding hobbyist will tell you: buying a new solder paste is similar choosing a new motorcar. At that place are then many options to consider. Honestly, every welding specialist or amateur will tell yous that simply 3 features actually matter when y'all buy these necessary elements:

- Lead-based or atomic number 82-costless structure;

- Alloy ratio;

- Water-washable or no-clean;

I decided to focus on these three parameters as well. I picked thirty different products and tested them in equal conditions, more than or less. The results are reflected in the rating you lot see on this page. The selection wasn't that difficult but there are a few factors a seller may hide or "forget" to mention when you purchase this paste.

Is Soldering Paste the aforementioned as Flux?

No. solder paste contains tiny balls of solder mixed with a flux agent. Flux by itself contains no solder and is merely a paste or gel.

How did I select 3 major products for my rating?

- Temperature Solder Paste is fully compatible with T4 industry standard;

- MG Chemicals has a great "wettability" charge per unit and useful dispenser;

- 247 is another T4 industry standard paste, with 2 dispensing tips;

Other picks in my list are also good, at least, according to my tests. All brands are reputable enough to recommend – ChipQuik, Grade, Silver Like shooting fish in a barrel, Kester, etc.

Really, you should ask yourself earlier buying – what strengths, backdrop, operating temperatures, preferred method of soldering, different metals, and compatibility with welding machines do I need? Yous may inquire your questions here, be happy to assist if I can. Make sure to leave your comments nearly this guide. I can make mistakes and bad choice that is why I try to update each written review regularly. Thanks for reading!

Video Tutorial: Using Solder Paste

What is Solder Paste used for?

Solder paste is made of tiny solder assurance mixed with flux and is used in soldering parts to a blank circuit board. The solder paste melts in one case put in a reflow oven and the parts are soldered to the lath.

Solder vs Solder Paste

Solder comes in a wire-like spool, while solder paste comes in a jar and is made of tiny solder balls mixed with a flux amanuensis.

Source: https://solderingironguide.com/best-solder-paste/

0 Response to "Chipquik Solder Paste in Jar 50g (T3) Sn63/pb37 Review"

Post a Comment